|

|

| Services - Speciality Services | |

Reducing Energy Since, the cost of energy constitutes a major component of cement manufacturing current attention all over is focused on restricting the same. With the cost reduction in mind, we have implemented many modifications especially in the following areas:

The above areas of modifications are aimed at overall pressure drop reduction. The pressure matrix in the pre heater cyclones and the pressure drop across the pre heater tower is one of the main criteria resulting in the fans having increased power consumption. By easing out the pressure drop, through the above modification strategies, there is considerable reduction in the fan power. Along with the above, our modifications optimized the power consumption by improved efficiency, stable operation, reduced starvation and operating at fairly in a straight performance curve rather than drooping curve. This also leads to enhanced capacity utilization at the same power rating, obviously, another kind of energy conservation. |

|

The aim of the specialty assignment is mainly to study at Pre Heater Kiln and Calcinor Cyclone circuit and Fans by carrying out measurements; take inference from the present operating conditions of the plant, and establish the strategic requirements to fulfill the objectives primarily focusing on Energy Savings. The main objective has been summarized through

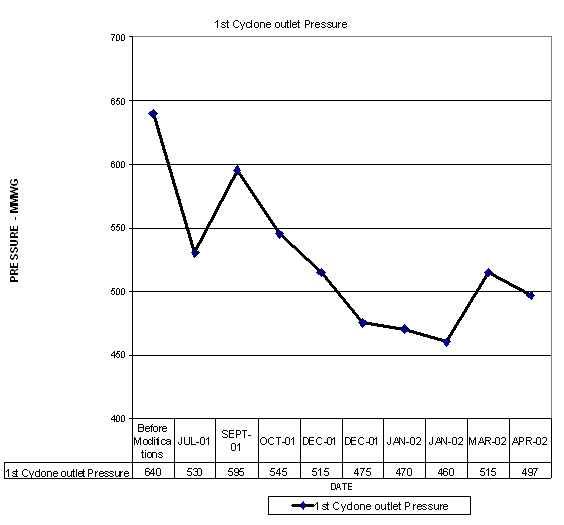

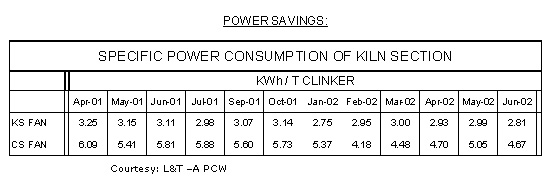

We are pleased to inform you that most of the field results implemented at M/s. Larsen & Toubro Ltd.,( Ultra Tech Cement Ltd.,, Presently Aditya Birla Group) APWorks, Gujarat Cement Works, M/s. Narmada Cements Ltd, M/s. Ambuja Cements Ltd., Kodinar. M/s. Binani Cements Ltd, M/s. Madras Cements group of units, recently at Hirmi Cemetns are astonishingly encouraging and yielded substantial energy saving. For your kind information and reference we are enclosing herewith a graphical & tabular representation of progressive modification and corresponding results being achieved at L&T -APCW Unit. As a major break through, our this innovative methodology of Reducing Energy By Static Part Modification in Fans and Cyclones has been accepted under the Copy Right registration and Government of India Copy Right office has duly registered the same under Copy Right Registration act vide their registration No: A – 73152/2005 on the file of 2003.

The following is a graphical & tabular representation of progressive Pressure Drop Reduction after each modification and result that is achieved in Power savings:

|

|

Copyright © 2007 Vibcon Services Private Limited. All Rights Reserved. |