|

|

| Services - Vibration Analysis | |

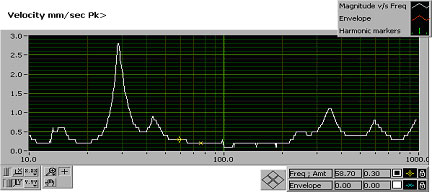

The primary goal of maintenance management today is to increase equipment reliability by effectively managing machinery wear and failure prevention. Currently it is commonly accepted that over 90% of all rotating machinery failures contain excessive levels of vibration. The use of predictive technologies such as Vibration Analysis has therefore proven to be an effective means of measuring and quantifying the condition of plant equipment.

|

|

Vibration Analysis Programme consists of:

Our Vibration Analysis techniques provide extensive data for assessing Equipment Condition during its operation. Information gathered from this testing provides a means for planning shutdowns well in advance of potential failures. Scheduled shutdowns enable production to avoid the unanticipated high cost of catastrophic failures. The use of Vibration Analysis as a diagnostic tool helps identify root causes of problems such as misalignment, imbalance and resonance. All of these conditions can be diagnosed, corrected and confirmed using vibration diagnostic techniques. Our team performs these technologies efficiently and effectively and provides diagnostic reports in order to correct these problems when identified. Helping plants design and implement predictive maintenance programs is our primary services. |

|

Copyright © 2007 Vibcon Services Private Limited. All Rights Reserved. |